|

EPS Production Line(EPS Machine)

3D Wire Panel Line

XPS Board Production Line

EPS Sandwich Panel Line

PU Sandwich Panel Line

|

|

Products>>EPS Production Line>>What is EPS ?

What is EPS ?

| What is EPS? |

EPS Application |

|

|

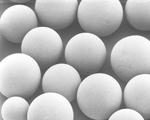

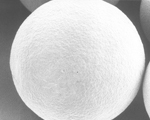

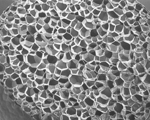

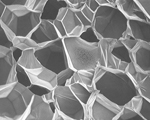

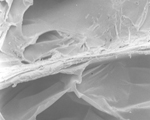

Expanded Polystyrene (EPS) is a lightweight cellular plastic material consisting of small hollow spherical balls. It is this closed cellular construction that gives EPS its remarkable characteristics.

EPS is produced in a wide range of densities providing a varying range of physical properties. These are matched to the various applications where the material is used to optimise its performance and strength.

|

|

|

|

| EPS under microscrope |

EPS under microscrope |

EPS under microscrope |

EPS under microscrope |

|

|

|

|

| EPS under microscrope |

EPS under microscrope |

EPS under microscrope |

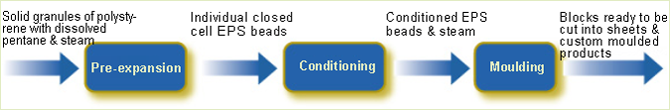

How is EPS made?

EPS is produced in a three stage process:

(1) Pre-expansion

Upon contact with steam the pre-foaming agent found within the polystyrene beads (usually a hydrocarbon such as pentane) starts to boil and the beads are expanded to between 40 to 50 times their original volume.

(2) Conditioning

After expansion the beads undergo a maturing period in order to reach an equilibrium temperature and pressure.

(3) Moulding

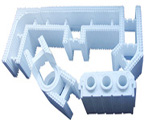

The beads are placed within a mould and again reheated with steam. The pre-foamed beads expand further, completely fill the mould cavity and fuse together. The beads are moulded to form boards, blocks or customised products.

There are two moulding processes for EPS.

Block moulding produces large blocks of EPS which can then be cut into shapes or sheets for use in both packaging and construction applications.

Shape Moulding produces parts which have custom designed specifications. Electronic product packaging in particular is where shape moulded EPS is used extensively. When moulded, nearly all the volume of the EPS (~98%) is air.

Properties of EPS

EPS has been a material of choice for over 40 years because of its technical versatility, performance and cost effectiveness. It is widely used in many everyday applications where its light weight, strength, durability, thermal insulation and shock absorption characteristics provide economic, high performance products.

(1) Light Weight

EPS is an extremely lightweight material which is not surprising considering it is comprised of ~95% air. This characteristic makes it ideal for use in packaging as it does not significantly add to the weight of the total product thereby reducing transportation costs. Energy consumption for transport fuel is also reduced and vehicle emissions minimised ĘC all contributing to lower global warming.

(2) Durability

The exceptional durability of EPS makes it an effective and reliable protective packaging for a wide range of goods. The cellular structure of EPS makes it dimensionally stable and therefore does not deteriorate with age. EPS is also odourless and non-toxic.

(3) Moisture Resistance

EPS is a closed cell material and does not readily absorb water. There is no loss of strength in damp conditions, making EPS ideal for cool-chain products. The material is moisture resistant, so the highest hygiene requirements are met. The ability of EPS to resist moisture also lends itself for use in fishing floats and marina buoys. Even when subjected to prolonged saturation in water, EPS will still maintain its shape, size, structure and physical appearance with only a slight reduction to its thermal performance.

(4) Thermal Efficiency

The superior thermal efficiency of EPS makes it ideal for packaging any product that is sensitive to temperature change. Products enclosed in EPS containers can be maintained for long periods at temperature above or below ambient conditions and can be protected from sudden temperature changes that can occur in the transport through different climatic zones. Examples include fresh produce and seafood as well as pharmaceutical and medical products.

(5) Shock Absorption

EPS exhibits excellent shock absorbing characteristics making it the first choice for packaging of a wide range of products including appliances, electronic products, computers and chemicals

(6) Versatility

EPS can be manufactured to almost any shape or size, or it can be easily cut and shaped when required to suit any application. EPS is also produced in a wide range of densities providing a varying range of physical properties. These are matched to the various applications where the material is used to optimise its performance. In addition, EPS is also compatible with a wide variety of materials.

(7) Ease of Use

For building and construction applications, EPS is considered to be one of the easiest materials to install on site. It is normally supplied in sheet form however can also be moulded into shapes or in large blocks.

|

|

(1) Packaging

EPS is used widely as a packaging medium for a variety of products. Its exceptional shock absorbing characteristics make it ideal for the storage and transport of fragile and expensive items such as electronic equipment, chemicals and wines. The thermally insulative and moisture resistant properties of EPS enables freshness extension of perishable products such as produce and seafood. Moreover, its compression resistance means that EPS is ideal for stackable packaging goods. The majority of EPS packaging manufactured in Australia is used in the transport of fruit, vegetables and seafood. EPS packaging is used extensively for both the domestic and export market.

(2) Building and Construction

Considerable quantities of EPS are also used in the building and construction industry. EPS is an inert material that does not rot and is not susceptible to attack by pests such as rats or termites. Its strength and durability makes it a versatile building product however its primary use is as custom insulation in building applications ranging from walls, roofs and floors. It is also used as a void-forming fill material in civil engineering projects, as a lightweight fill in road and railway construction, and as floatation material in the construction of floating pontoons and yachting marinas.

(3) Other

When safety is paramount, EPS comes into its own. It is used in the manufacture of children's car seats and cycling helmets, where its protective qualities such as strength and shock-absorbency are vital. EPS also has applications in horticulture as seedling trays. Granulated EPS can also be added as a soil conditioner to promote aeration of the soil.

|

|

|

|

| Fish box |

Wall element |

Celling sheet |

Decoration elements |

|

|

|

|

| Concrete wall element |

Floor heating |

Fruit box |

Celling board |

|

|

|

|

| Seed tray |

EPS cup |

Decoration elements |

Celling board |

|

|

|